MON 25AUG2014, Middlebury, CT

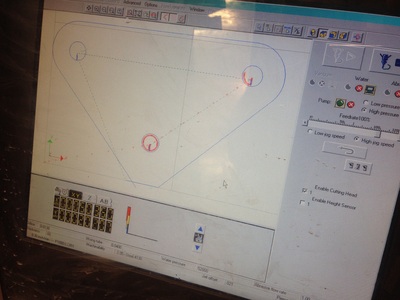

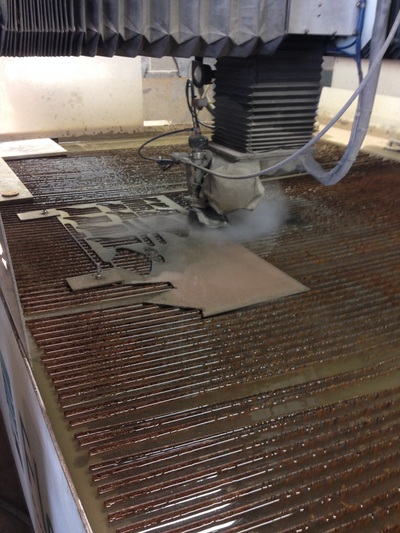

This past week my friend Ed and I entered many of the HM-14 brackets into CAD. This past Saturday, we began cutting them out on his water jet. It's amazing how fast it can cut .080" 4130 steel sheet! And they come out so perfect looking. Where needed, we bent them on his brake and a couple I needed to wait to drill until I mounted things on the aircraft, as I deviated in some cases from the plans- instead of using 20mm x 20mm wood for the longerons and cross bracing of the fuselage, I used 7/8"- a little wider. The inner brackets are OK, but since the outer ones that match up need to wrap around a longer distance- a straight copy from the plans mean they won't line up- this is where cutting out and fitting cardboard templates can really help.

I also worked on the rudder parts and cockpit control linkage- the yoke, etc.

This past week my friend Ed and I entered many of the HM-14 brackets into CAD. This past Saturday, we began cutting them out on his water jet. It's amazing how fast it can cut .080" 4130 steel sheet! And they come out so perfect looking. Where needed, we bent them on his brake and a couple I needed to wait to drill until I mounted things on the aircraft, as I deviated in some cases from the plans- instead of using 20mm x 20mm wood for the longerons and cross bracing of the fuselage, I used 7/8"- a little wider. The inner brackets are OK, but since the outer ones that match up need to wrap around a longer distance- a straight copy from the plans mean they won't line up- this is where cutting out and fitting cardboard templates can really help.

I also worked on the rudder parts and cockpit control linkage- the yoke, etc.